Polyurethane Based Nanocomposites

Thermoplastic polyurethanes, polyurethane-ureas, polyureas (TPUs) constitute one of the most important and versatile classes of thermoplastic elastomers. TPUs are segmented copolymers containing alternating hard and soft segments along a linear macromolecular backbone. Segmented TPUs generally display two-phase morphology, where hard segments act as reinforcing fillers in a continuous soft matrix. The soft segments in TPUs originate from hydroxyl or amine terminated oligomers with glass transition temperatures (Tg) well below room temperature, such as aliphatic polyethers and aliphatic polyesters, whereas the hard segments consist of diisocyanate and a chain extender such as a low molecular weight diol or diamine.

Our research mainly focuses on the investigation of critical design principles for the production of high-performance TPUs in a close collaboration with Koc University. Along with this, we are particularly interested in the production of advanced functional nanocomposites consisting of TPU matrices and various inorganic fillers like silica nanoparticles.

Green Composite Materials

Critical environmental and economic issues have been stimulating research in the mass production of sustainable materials for plastics market that favors low costs and high production rates for decades. Along with new industrial regulations and growing technological needs, green composite materials have attracted particular interest as promising alternatives to petrochemical-based plastics and their composites.

Our research mainly focuses on the production of Poly(lactic acid) (PLA) based composites with enhanced mechanical properties like stiffness, strength, and impact resistance.

Silicone-Based, Synthetic Tissue And Organ Models For Surgical Simulation

Lack of cadavers and fresh tissue/organ models hinders the quality of medical education; therefore, there is a need for a reliable and sustainable training medium for evergrowing number of medical students and personnel. In Akbulut research group, we design silicone-based surgical models that are engineered to simulate mechanical responses of real organs to incision, dissection, and suturing. Until now, we have developed skin, breast, and vascular models. Different suturing techniques, benign mass removal, and complicated oncoplastic surgery can be practiced on these models. We aim to improve the quality of surgical trainings via practical, affordable, and tactile simulation platform. This research resulted in a spinoff company, Surgitate, which now sells these models in several countries.

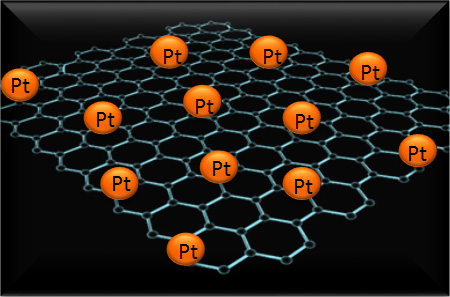

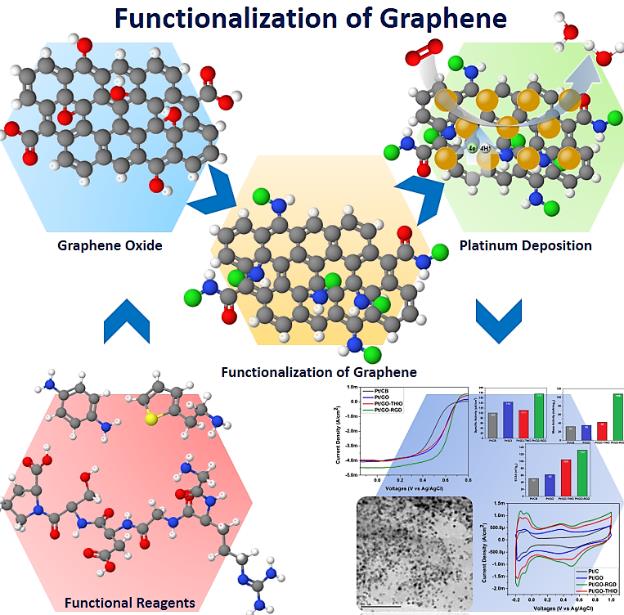

Functionalized Graphenes

Graphene based nanomaterials are highly important because of their unique properties such as high contact surface area, high electrical conductivity and their enormous stability. Graphene and related materials have been used as promising catalyst supports in energy conversion and storage applications. In our research, in order to produce more efficient catalyst supports, we successfully modified graphene with various active functional groups such as amine, thiophene, fluorosilane, and RGD peptide by mono and multi-functionalization of graphene oxide. Further, modified polyol process was used to obtain specifically guided growth of Platinum (Pt) nanoparticles on these modified graphene surfaces. Consequently, better dispersion of Pt nanoparticles were obtained with delicate control-ability. As a result, the electrocatalytic activity (ECSA and ORR) was greatly enhanced. These promising nanomaterials can serve as potential candidates for high performance polymer electrolyte membrane fuel cells.

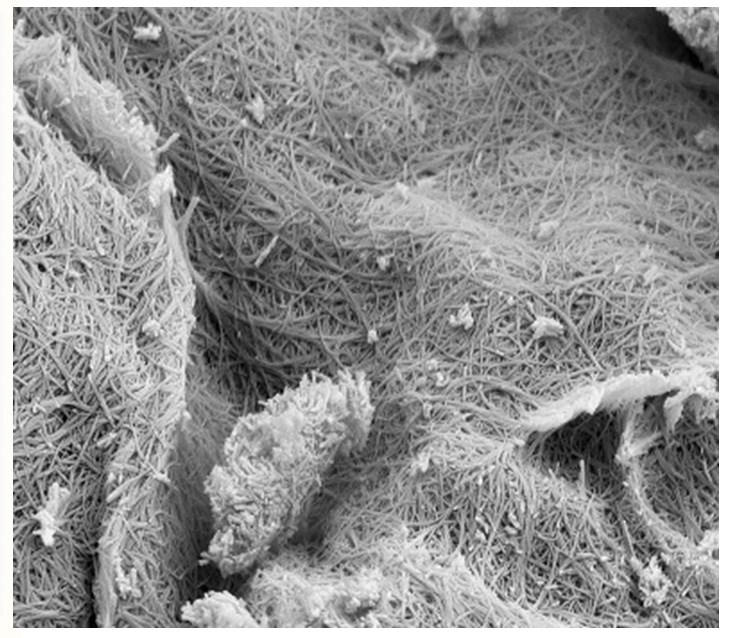

Graphene/polymer Nanocomposites

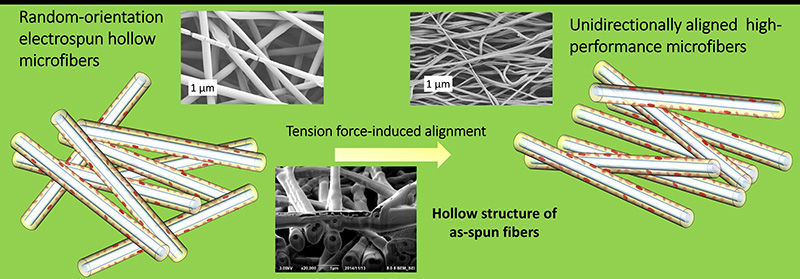

In this work, superior electrical, mechanical and antibacterial properties of graphene nanosheets were readily incorporated in electrospun poly (vinyl alcohol) (PVA) fibers. The major advantage of this approach is that via co-solvent addition method, a well-dispersed hydrophobic graphene nanosheet distribution in hydrophilic PVA solution was achieved. Thus, improving the final fibers' mechanical and electrical properties. As the final stage of this investigation, effectiveness of this method in preparation of ternary PVA/PANI/rGO fibers and their antibacterial performance was studied. It was shown that effective distribution of conducting components in biodegradable PVA fibers resulted in high antibacterial activity of the final electrospun mats.

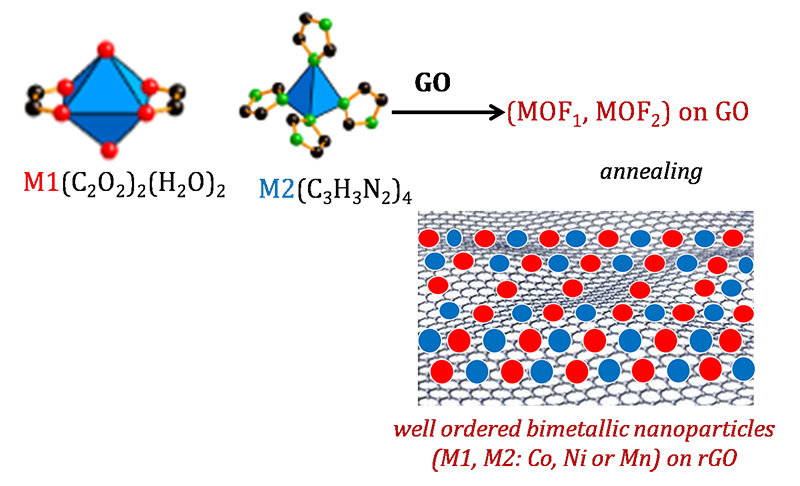

Metal organic frameworks

Metal-organic frameworks (MOFs) are a new class of porous, highly crystalline materials consisting of metal nodes connected by organic linkers. Due to the simplicity of manipulating or substituting the metal centers and ligands, there are limitless number of possible combinations, which is attractive from a design standpoint. MOFs exhibit many unique properties due to their tunable pore sizes, thermal stability, high volume capacities, large surface areas, and desirable electrochemical characteristics. Our aim is to prepare well dispersed and ordered metal nanoparticles (Ni, Co or Mn) on graphene. For that purpose we have been synthesizing graphene supported MOFs first and then by annealing (to remove organic parts) we will achieve desired catalyst layer. It is also possible to obtain bimetallic nanoparticles starting from two diffent MOFs.

Rheology of Cement

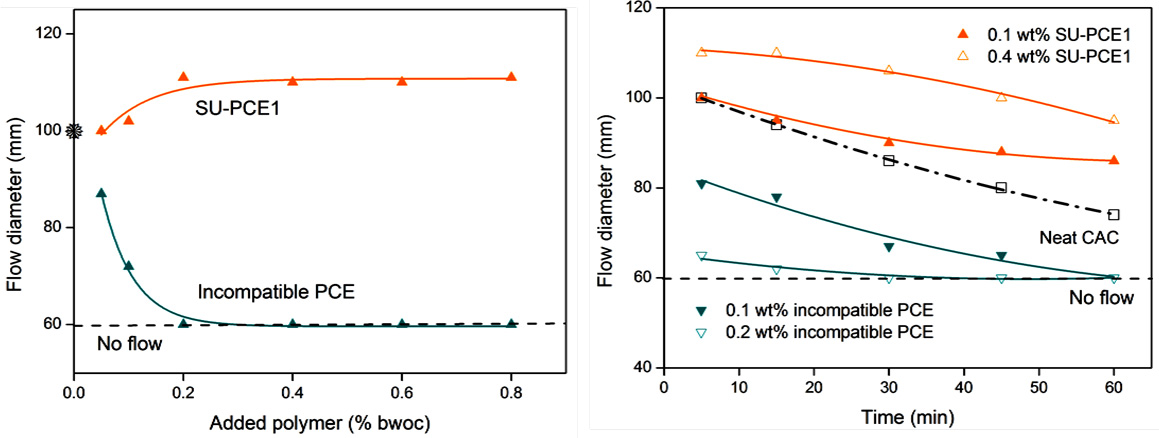

We develop superplasticizers for ordinary Portland cement (OPC) and calcium aluminate cement (CAC). Poly(carboxylate ether)-based superplasticizers (PCEs) are used to modify the viscosity, slump flow, and slump retention of cement mixtures... (EP 3056476 A1)

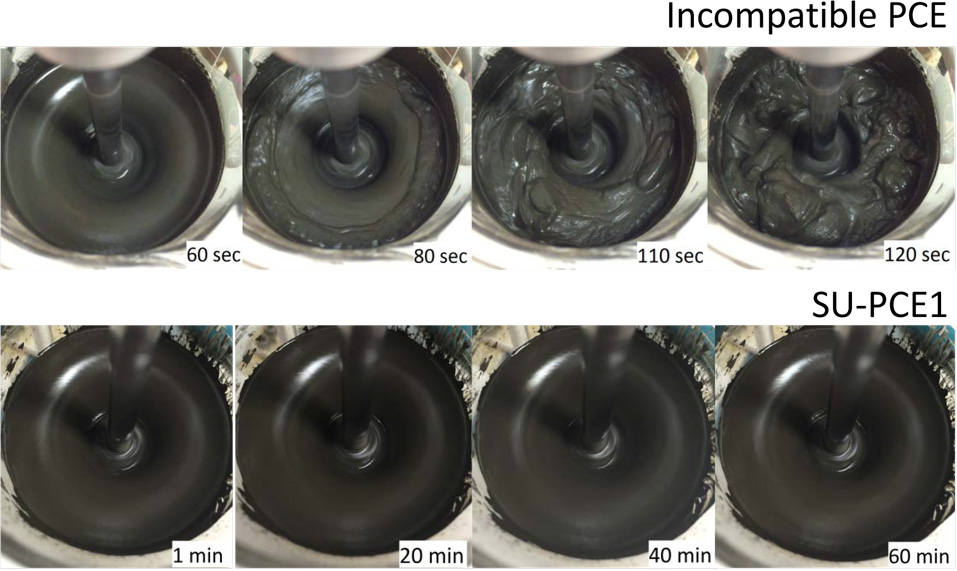

Below are the pictures of CAC systems with an incompatible superplasticizer (top) and with the superplasticizer that we designed (SU-PCE, below). An addition of 0.4 wt% SU-PCE is enough to preserve the flowability of CAC in longer time periods.

Fuel Cells

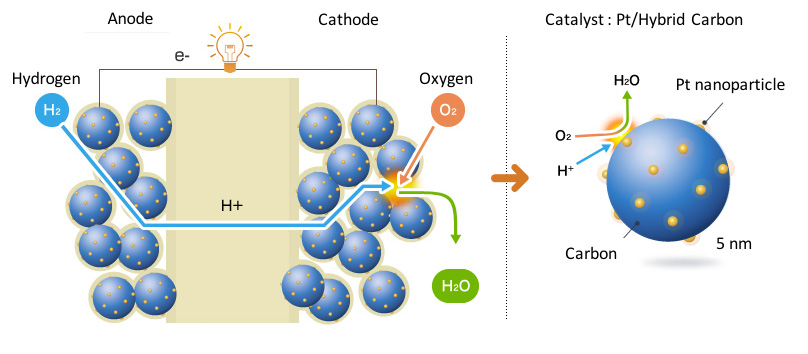

Graphene-Based Catalysts and Electrodes for Fuel Cells

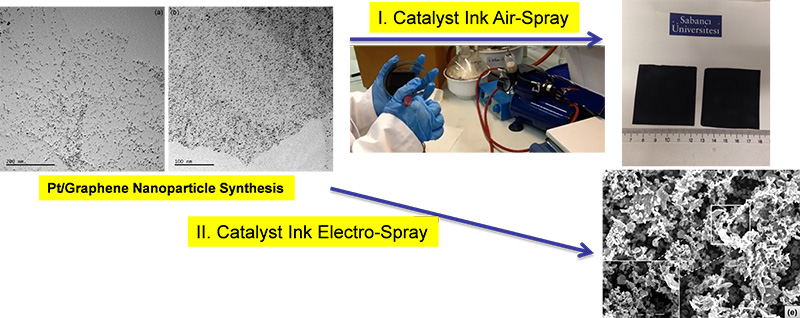

Despite enormous progress in polymer electrolyte membrane (PEM) fuel cells, development of catalysts with maximum activity and durability and minimum loading are still the core challenges. Catalyst supports are also very important in this respect. Generally, proper catalyst support materials must have large specific surface areas to support catalyst nanoparticles, high electrical conductivity to promote fast electron transfer, strong affinity towards the nanoparticles and stability under the operating conditions to provide stable catalyst structures. We employ various carbon materials such as graphene, carbon black, carbon fibers and their hybrids as the catalyst support. We develop graphene based electrodes and electrode fabrication methods to enhance the dispersion, utilization and the durability of the Pt catalyst at the same time to reduce the Pt loading. The reduction of catalyst amount in the electrode without sacrificing the performance and thus lowering the cost of fuel cell is the ultimate goal. Highly uniform and well dispersed graphene supported Pt (Pt/graphene) catalyst nanoparticles are chemically synthesized to be used as the catalyst layer of fuel cell electrodes. Synthesized Pt/graphene electrocatalysts are applied via air-spray or electro-spray to have electrode structure. By the improved technique of our group, PEM fuel cell efficiency increased. That work is carried out as a part of Graphene Flagship Project

Polymer Electrolyte Membranes for Fuel Cells

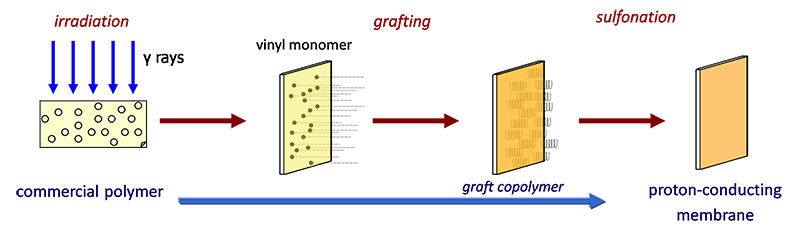

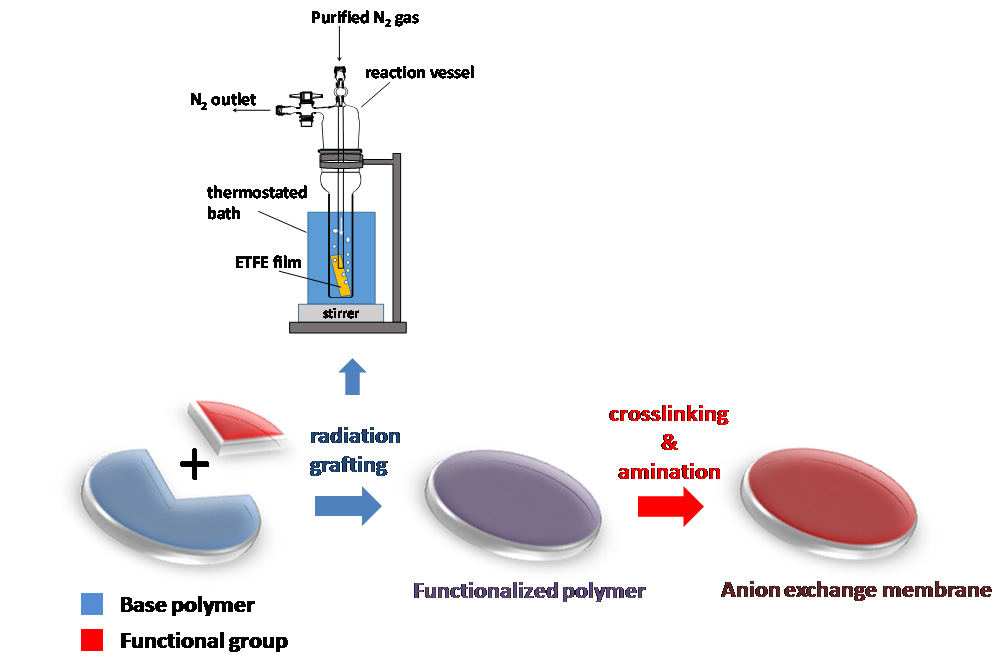

Radiation Grafted Membranes for Low Temperature Fuel Cells

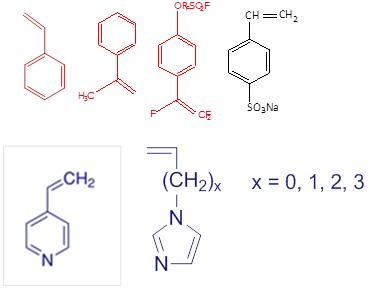

Fuel cells are one of the most promising electrochemical power sources both for mobile and stationary applications. Among others, the polymer electrolyte membrane (PEM) fuel cell has received great attention due to their high power density, quick start-up time, pollution free operation and compact structure. The development of cost effective proton exchange membranes to replace the state-of-the-art high cost perfluorinated membranes is an important challenge. The radiation induced grafting, a versatile technique allowing the functionalization of the base material for the introduction of a desired property, offers several advantages. Homogenous, highly conducting and low cost proton exchange membranes have been developed for fuel cells having comparable performance with that of Nafion®.

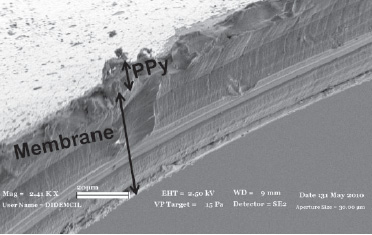

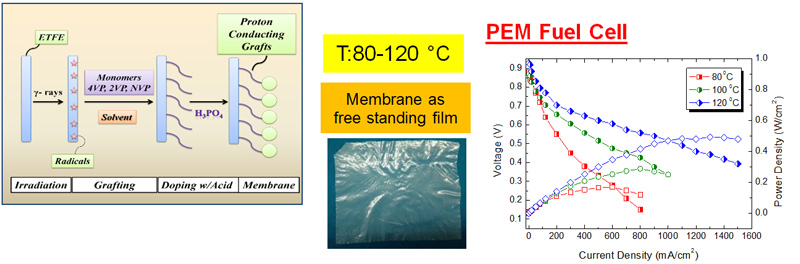

Radiation Grafted Membranes for High Temperature Fuel Cells

Most of those shortcomings arise when the operation temperature is limited to below 100 °C (typically 60-80 °C), at atmospheric pressure which is in turn limited by the current state-of-the-art membranes such as Nafion® because of its water assisted conduction mechanism. Nafion® membranes have advantages such as high mechanical and chemical stability at temperatures below 100 °C and high proton conductivity in hydrated form as well. However, the water requirement in the membrane limits the operation temperature to below 100 °C in theory. Thus, the synthesis and characterization of proton conducting membranes constitutes a significant step for the development of high temperature PEM fuel cells. Our focus is the preparation of phosphoric acid doped proton exchange membranes to operate at high temperature (especially above boiling point of water) and water free conditions for PEM fuel cells. Owing to a simple manufacturing process, radiation-induced grafting, the procedure that is offered to fabricate high temperature membranes is able to overcome casting (or manufacturing) problems of other high temperature membrane candidates. Nitrogen containing monomers are selected since strong interaction with phosphoric acid to create N-H interaction to operate at high temperature is expected. The resultant membranes exhibit promising thermal and mechanical properties, lower water uptake and encouraging proton conductivity. Moreover, both the ex situ proton conductivity measurements and fuel cell testing prove that these membranes are very promising to operate at high temperature and dry fuel cell operation conditions.

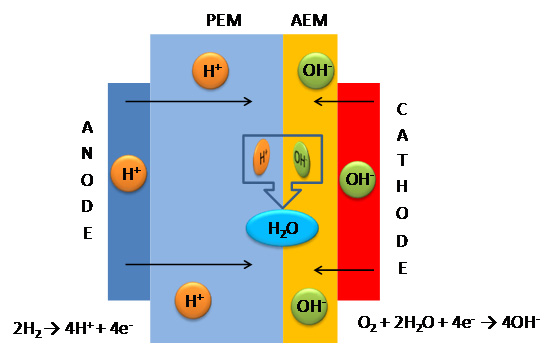

Mixed Cation- and Anion-Exchange Hybrid Membranes for Fuel Cell Applications

Bipolar membrane fuel cells (BPMFCs) can self-humidify to ensure high ionic conductivity and allow the use of non-Pt catalysts. This novel membrane electrode assembly (MEA) represents bipolar (hybrid) membranes composing of both cation (proton) and anion exchange membranes laminated together. Self-humidification is created at the bipolar membrane interface. Anion exchange membranes are the most critical components of a bipolar membrane. Hence, in addition to proton exchange membranes, we report on the design and development of crosslinked anion exchange membranes (AEMs) which are synthesized by radiation grafting and subsequent functionalization (amination and crosslinking). The aim is to verify one-step synthesis of crosslinked AEM for bipolar membrane fuel cells (BPMFCs).

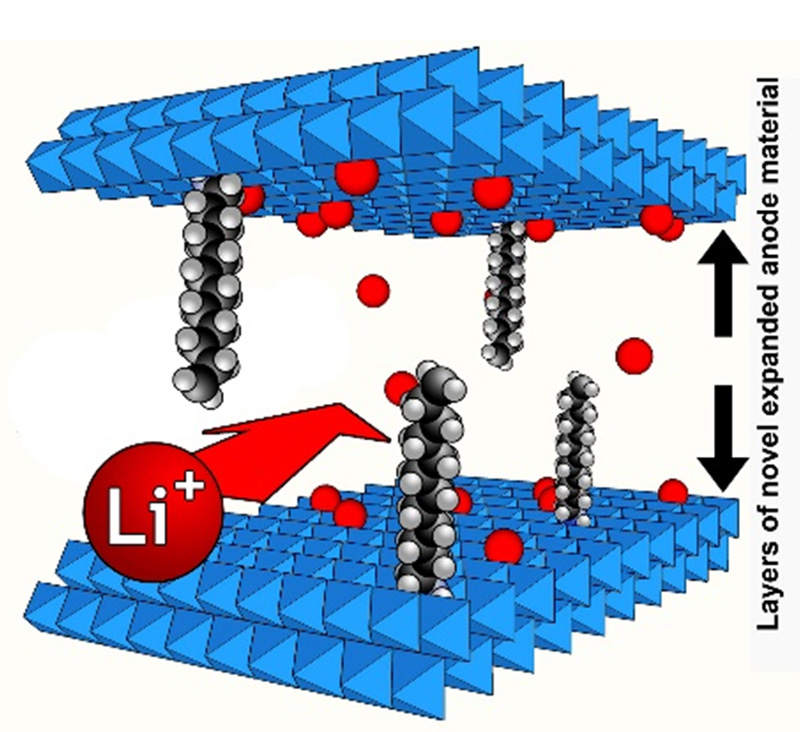

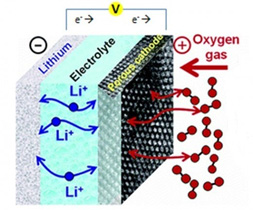

Batteries

Li-ion batteries are the most used electrochemical battery type in mobile applications. In near future, the demand for high energy, high power batteries will increase due to the increasing demand for electric vehicles and renewable energy resources. Therefore, the high energy and high power batteries will be provided by the developments in cathode active materials. Lithium-air (Li-air) batteries are one of the most promising candidates of energy storage for portable applications and electrical vehicles due to their high energy density. However, there are still various problems to be solved and several limitations to overcome for commercialization of Li-air batteries. In this regard, especially the development of catalysts and electrodes, which influence significantly the battery performance, is an important issue. As the battery group here in Sabanci University, we are mainly working on the development and synthesis of novel anode and cathode materials for Li-ion and Li-air batteries. Our competence is on carbon, and metal/metal oxide materials. With our extensive experience in material synthesis, we are able to synthesize unique composite materials and morphologies. These materials, thanks to their structures, perform better and have much higher activities.

Artificial Muscles

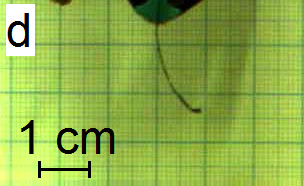

Polymeric actuators are materials that convert electrical stimuli to mechanical displacement. Conjugated polymeric actuators among all types of actuators have a unique position, due to simple and low cost preparation, flexibility, light weight, and good mechanical properties. Owing to these features, they are considered as promising candidates for mimicking natural muscle behavior for which they are sometimes called “artificial muscles”. Generally, actuators based on electroactive polymers are divided into two main subgroups; electronic electroactive polymers, and ionic electroactive polymers. Our research field focuses on ionic electroactive polymer actuators, such as polyaniline with novel morphological features. In ionic electroactive polymer actuators, migration of ions between polymeric chains due to external electric field is the principal mechanism of mechanical strain. According to specimen geometry, this strain can be converted to linear or bending mm-scale displacement. Figures below illustrates bending of a polyaniline actuator strip in air by applying a 0.5 V potential.

Separation Membranes

In our laboratory we design and develop smart hybrid membranes using initiated Chemical Vapor Deposition technique for protein separation applications. For this purpose, stimuli responsive and conductive polymer coatings are used to prepare the membranes. Effects of polymer type, membrane geometry, coating thickness on the separation performance is investigated.

Controlled Delivery

In our laboratory we develop stimuli responsive and conductive polymer nanostructures for controlled delivery applications. We use model molecules to study the early time kinetics of release from the developed nanostructures. Stimuli responsive polymers are employed to achieve triggered response. By tuning the shape of the nanostructures and the polymer composition release kinetics can be controlled.

Sensors

In today’s world many diseases are accompanied with odors which means that detection of volatile organic compounds at high sensitivity and selectivity can make early diagnose possible. With that motivation, conducting polymers with varying nanostructures are produced in our laboratory with predetermined properties and used as a sensing material for gases. While electron acceptor gases can remove electrons from the aromatic ring of a conducting polymer polypyrrole, electron donating gases have the opposite effect. This leads to a change in conductivity and a highly sensitive detector for volatile organic compounds can be developed by monitoring conductivity change. In addition to VOC sensors, our group is also working on developing humidity sensors using conductive polymeric nanostructures.

In our group, we also design bio-active smart polymeric surfaces for immobilization and separation of proteins. Bio-active smart polymer surfaces are produced using initiated chemical vapor deposition (iCVD) technique, followed by functionalization of the surface with high performance immobilizer (ligands) and stimuli responsive polymers. Improving the mechanical properties of the polymer films, increasing the immobilization capacity of ligands and studying the surface-protein interactions for a better control of attachment and detachment of proteins are within the framework of this project.

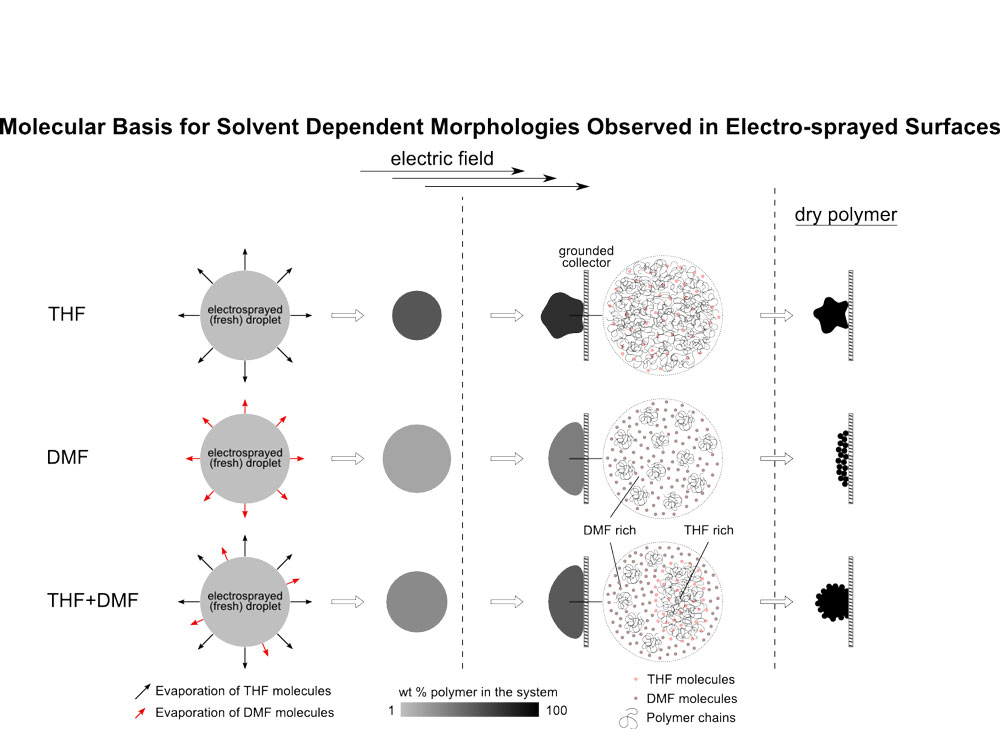

The Lotus Effect: Thanks to nature... Inspired by the ever clean, highly water repellent surfaces of Lotus (Nelumbo Nucifera) leaves, our team has been working on producing similar, superhydrophobic surfaces via electrospinning/spraying. Such biological or synthetic surfaces are unique with their microscopically rough topographies comprising micron, sub-micron and nanometer scale features, which allow very limited contact area at the liquid-solid interface when combined with non-polar outermost surface chemistry. Corresponding outcomes are remarkably high advancing water contact angles varying generally between 150 and 180o, and relatively low threshold water sliding angles as low as 0o, or pinned droplets (despite the high advancing contact angles) depending on the geometry of the surface topography. For achieving the desired final properties, both the chemistry and the topography of the surface must be engineered, as our team has been realizing via co-polymer synthesis and electrospinning/spraying, respectively.

Our approach to copolymer design is straightforward; the monomer that will dominate the polymer backbone is selected according to the desired bulk properties of the final coating, and polymerized with a relatively low amount of a non-polar component (e.g. a fluorinated monomer or a crosslinker) which will dominate the outermost surface for minimizing the surface free energy. The coating is then formed from the copolymer via electrospinning/spraying. One example is solvent resistive superhydrophobic surfaces of copolymers having reactive groups such as isocyanate or epoxy, which can be crosslinked during or after electrospinning/spraying. Another example is perfectly hydrophobic surfaces, having practically no interaction with water (180o contact angles and 0o threshold sliding angles) achieved via a combination of self-assembly and particular electrospraying process control to form a dual scale roughness profile. We also perform theoretical investigation of the formation of topographical features. More than a decade of applied research has provided our group a solid capability to tune the wettability profile of a polymer surface using electrospinning/spraying.

Surface Video

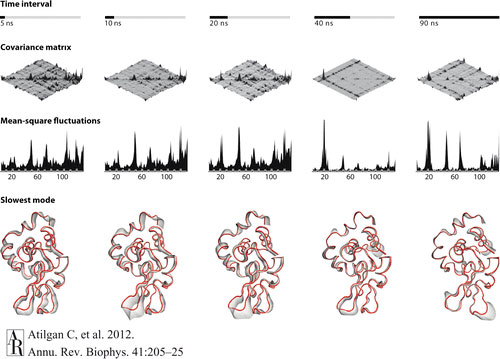

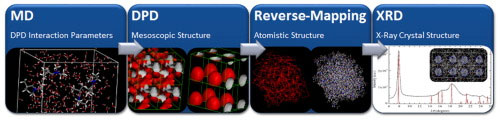

Our goal is to answer the why question instead of the how question for the observed behavior of materials using computational techniques as the tool. Our focus is on the dynamics of complex molecular systems. We address understanding of the working principles of molecular machines. We study organic self-assembled molecules in general, and proteins in particular. We utilize atomistic and coarse-grained simulations supplemented by theoretical developments to cover the pico-millisecond time scales, and nano-micrometer length scales. We have developed network-based models to study the basic features contributing to structure/function relationships in these systems. These include:

- Elastic network models in 1-D (GNM) and 3-D (ANM). (ANM server)

- Optimal paths along the networks to identify key locations participating in their proper functioning. (Available under Services)

- System identification based on perturbation/response scanning (PRS) to study the near-equilibrium dynamics. (PRS server)

- Prediction of relaxation times contributing to equilibrium fluctuations.